What is a line reactor and when do I use one?

Posted by Morgan Spano on Jun 6th 2022

Clean and consistent electrical currents are optimal for the health of your industrial equipment.

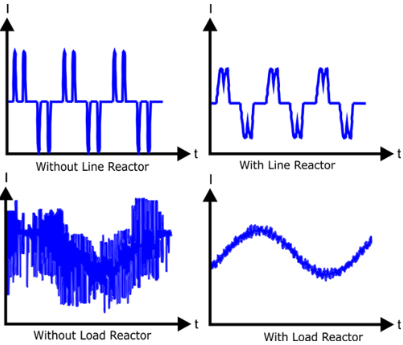

The addition of a line reactor, sometimes known as a choke or inductor, helps protect your equipment from input power disruptions that damage the drive.

Line reactors are electro-magnetic devices which consist of a steel core wrapped with copper coils. The coils form a magnetic field which current flows through limiting the rate of rise of current, reducing harmonics and protecting additional electrical devices. There are generally two types of line reactors used with VFDs; AC & DC.

When a reactor is installed between the power system and the VFD, it is known as an AC line reactor. When a DC reactor is inserted into the DC link of a drive, it is known as a DC link reactor.

Both AC and DC reactors act as harmonic current limiters but the AC reactor protects more equipment due to being installed between the VFD and power source limiting exposure to power system surges and fluctuations. This limits exposure to power system surges and fluctuations. Reactors can prevent overvoltage trips, increase the reliability and life span of the VFD, improve total power factor, and reduce nuisance tripping.

What is Impedance?

“Resistance in ohms but also commonly referenced in terms of percent when combined with the system voltage and line current flowing through the reactor.

That percentage then becomes the common term used to define the level of impedance for each rating of line reactor. That impedance functions to slow the rate of current changes in the line. The greater the current through the reactor, the greater the percentage of applied impedance will be.

If a reactor is said to have an impedance rating of 3% or 5%, that means the reactor will apply that specified percent of impedance when the current flowing through the reactor is at the rated current of the device,” TCI, Line and Load Reactor Basics.

Installing a line reactor on the input side of the VFD ensures protection to the drive but line reactors also have the capacity to be installed on the output side of the drive blocking potential incoming background line voltage harmonics.

“In almost all drive applications, the addition of an input AC line reactor is a low cost solution for drive protection and harmonic mitigation,” TCI, Line and Load Reactor Basics.

Want to learn more?

TCI has all sorts of helpful guides for incorporating a line reactor into your application:

When to install a line reactor?

- The input line power is known to have power surges, spikes, transients, etc.

- The supply line power is very stiff; greater than 10 times the kVA rating of the connected VFD.

- Where harmonic distortion is a concern. (IEEE-519 Harmonic Control in Electrical Power Systems)

- You want a buffer between your VFD and your motor to temper the waveform and reduce voltage stress on the motor

The general consensus seems to be the more current regularity the better, for all equipment across the board. If you’re ready to take the next step in harmonic mitigation; feel free to contact our sales staff at: [email protected] or get some help figuring the right reactor from our tech support at: [email protected].