Optimize your induction motor with WEG CFW320

Posted by Theresa Hoffman on Aug 7th 2024

Unlike direct current (DC) motors that offer built-in speed control, three-phase induction motors are primarily a fixed-speed device.

This characteristic, along with factors like power source, speed control, starting current and maintenance, can make them more challenging.

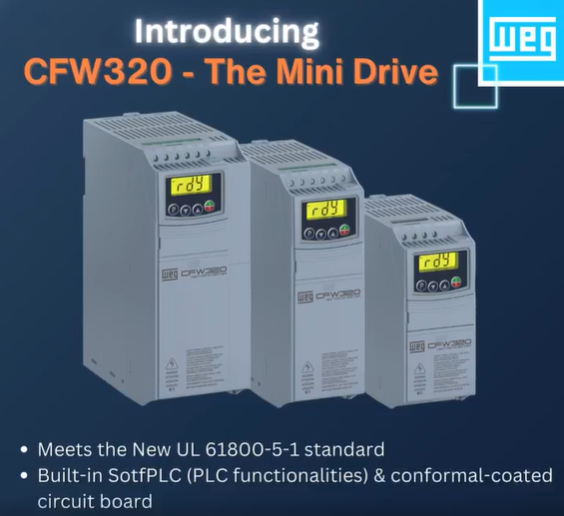

New in 2024, WEG introduces mini drive CFW320 to their VSD line. It’s designed to maximize efficiency, control, and protection for your three-phase induction motor, helping you keep it running at peak performance.

Precise Control

The advanced feature of vector control on the CFW320 goes beyond simple speed control.

Acting like a translator to interpret the ‘language’ of your motor’s current and voltage, it can determine the motors actual speed and torque output in real-time.

This precise control becomes particularly valuable when addressing common challenges with three-phase induction motors: the high inrush current surge during startup.

The CFW320 helps minimize this issue with various start-up control options, such as ramp-up control and soft starting.

These features not only reduce the stress on the motor and power supply during startup, but also pave the way for a smoother and more efficient operation.

Built-in HMI and SoftPLC

The built-in HMI and SoftPLC in the CFW320 eliminate the need for separate external equipment, making it a more compact design with reduced space requirements and simplified system complexity.

The user-friendly HMI allows for direct monitoring of motor performance data (speed, torque, etc.) on the screen.

Setting parameters, adjusting controls, and troubleshooting using diagnostic information and fault codes are all simplified.

Furthermore, the SoftPLC enables creation of custom logic programs for tailored motor control, with programming tools or pre-defined function blocks that reduce programming complexity.

Plug & Play Accessories

By adding slots onto the front of the unit, this allows the CFW320 to be even more flexible and adapt to various application requirements.

- Top Slots (Network Communication or Accessibility): These are used for optional modules like RS485, RS232 communication, Ethernet/IP, or Modbus communication, enabling network connectivity.

- Lower Slots (I/O Expansion): These accommodate modules for input/output (I/O) expansion, incremental encoder input, or a remote-control kit.

As an added benefit, a remote HMI is also available. This allows you to control and monitor the drive when it's not easily accessible.

Applications

- Centrifugal Pumps

- Fans / Blowers

- Blenders / Mixers

- Centrifuges

- Compressors

- Conveyors

- Roller Tables

- Granulators

- Commercial Dryers

- Rotary Filters

- Grizzly Feeders