Definite Purpose Contactors 101

Posted by Morgan Spano on Apr 12th 2022

Let’s start at the beginning. What are definite purpose contactors?

Originally designed for the HVACR industry, their use has expanded to a variety of other market segments. In general, if you have an application that heats, cools, refrigerates, controls, or moves air, then it is a likely candidate for these devices.

Unlike general-purpose relays, contactors are designed to be directly connected to high-current load devices. Relays tend to be of lower capacity and are usually designed for both normally closed and normally open applications. Devices switching more than 15 amperes or in circuits rated more than a few kilowatts are usually called contactors.

Apart from optional auxiliary low current contacts, contactors are almost exclusively fitted with normally open (“form A”) contacts. Additionally, contactors are designed with features to control and suppress the arc produced when interrupting heavy motor currents.

When current passes through the electromagnet, a magnetic field is produced, which attracts the moving core of the contactor. The electromagnet coil draws more current initially, until its inductance increases when the metal core enters the coil.

The moving contact is propelled by the moving core; the force developed by the electromagnet holds the moving and fixed contacts together. When the contactor coil is de-energized, gravity or a spring returns the electromagnet core to its initial position and opens the contacts.

Within the air conditioning OEM segment, DP contactors can be grouped into two main categories, depending on the application:

Compact 1- and 2-pole DP contactors

Ranges from 20 A to 40 A

- Often the prime choice for the unitary central air conditioning units installed in many home

- Standard AC coil voltages are 24 V, 120 V, and 240 V.

Standard frame DP contactors

Ranges from 15 A to 360 A

- Primarily used in the larger commercial/industrial air conditioning units that can be seen mounted on the rooftops of industrial plants, hotels, hospitals, office buildings, and other commercial and industrial installations. These air conditioning units carry ratings from a few tons to 500 tons.

- These are often used to control electric motors, lighting, compressors, elevators, pumps and cranes to pools, vending machines and food processing.

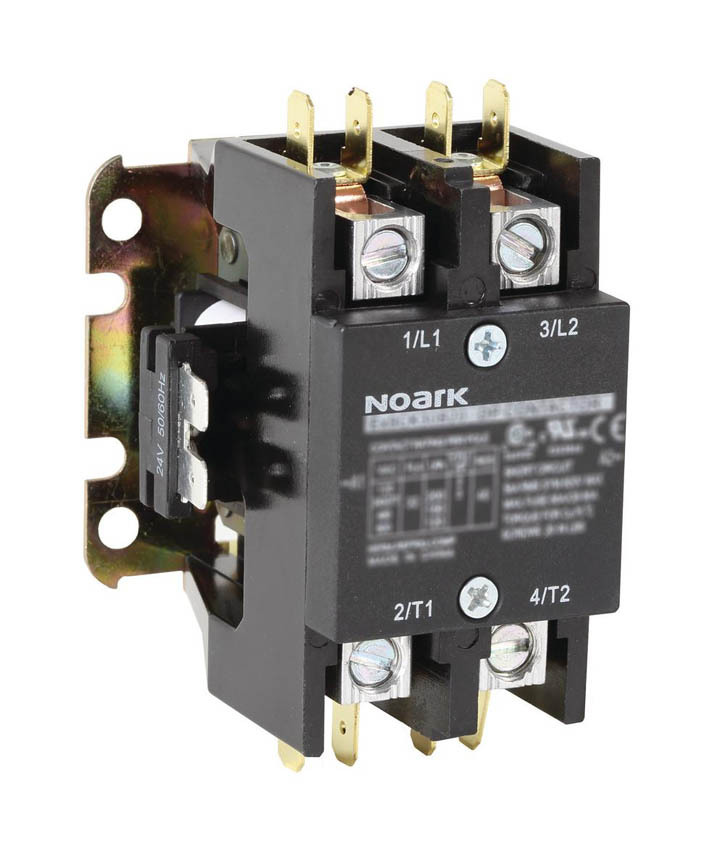

Basic Construction

A contactor has three components. The contacts are the current carrying part of the contactor. This includes power contacts, auxiliary contacts, and contact springs.

- The electromagnet (or “coil”) provides the driving force to close the contacts.

- The enclosure is a frame housing the contact and the electromagnet. Enclosures are made of insulating materials like Bakelite, Nylon 6, and thermosetting plastics to protect and insulate the contacts and to provide some measure of protection against personnel touching the contacts. Open-frame contactors may have a further enclosure to protect against dust, oil, explosion hazards and weather.

- A basic contactor will have a coil input (which may be driven by either an AC or DC supply depending on the contactor design). The coil may be energized at the same voltage as a motor the contactor is controlling, or may be separately controlled with a lower coil voltage better suited to control by programmable controllers and lower-voltage pilot devices.

DP contactors are generally easily interchangeable – if you are using another manufacturer you can most likely use ours without any issues. If you prefer, just call us with the manufacturer part number and we can cross it for you.

When specifying DP contactors, consider the following features:

- There are a broad range of contactors from 15 to 360 amperes; single-, two-, and three-pole devices; sealed housing limits contaminants and reduces or eliminates noise

- Compact and efficient design with a low VA coil and straight-through wiring; low VA current ratings

- Universal mounting plate that eliminates changing hole patterns when replacing devices

- A variety of terminal styles to fit specific application requirements; snap-on accessories that require no tools

- Simple coil change; convenient no-position sensitive mounting benefits

- Hassle-free installation and maintenance

- Devices furnished with pressure plates and (standard) quick connect terminals

- Availability of snap-on mechanical interlock, which allows interlocking two contactors for reversing or two-speed applications.

Still unsure of which contactor to order? Our Tech Support would be happy to help you decide and may start off asking the following questions:

Email or call our Tech Support at (847) 658-8130 and they’d be happy to help you determine which DP contactor is right for your application.