All About Photoelectric Sensors

Posted by Marshall Wolf on Jul 20th 2022

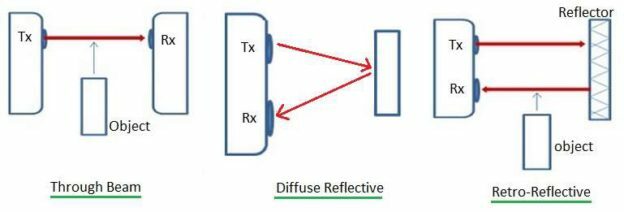

Let’s talk about sensors! As the automation industry becomes, well…more automated, photoelectric sensors have become a necessity to almost any production line.

Whether sensing temperature, fluid levels, or minute quality details, photoelectric sensors continue to become more refined. To better assist you with deciding which sensor will work best with your application we decided to share a quick synopsis on a few of our most popular photoelectric sensors.

Check out this great video from Realpars detailing photoelectric sensors!

Let’s start off with Thru-Beam Sensors:

Most likely the first kind of sensor the everyday consumer first thinks of, whether it’s the sensor in your garage or the complete Hollywood cliché of red laser trip wires in every spy movie.

- Reliable sensing in dirty environments

- Long-detecting distance

- Stable detecting position

- Opaque objects detectable regardless of shape, color or material

- Powerful beam

.

Able to detect down to a resolution of 0.03mm, thru-beam sensors are capable of detecting objects regardless of angle of incidence, surface characteristics, color of the object as long as they maintain direct alignment.

- Stack height

- Conveyors, package detection

- Skewed lid detection

- Parts counting

- Tool verification

- Part presence

- Error proofing

Retroreflective Sensors

Closer to what we may consider echolocation, a retroreflective sensor is positioned across from a reflective tape or cube and detection occurs something blocks the constant reflection.

Retroreflective Sensors (aka reflex, retro, or polarized retro-reflective)

- Reflector allows installation in a limited space

- Simple wiring

- Longer detecting distance than the diffuse-reflective sensor type

- Easily-adjustable optical axis

- Opaque objects detectable regardless of shape, color, or material

- Detects clothing, textiles, dust, sand

Applications

- Parts counting

- Conveyors

- Clear glass detection

- Error proofing

- Gate control

- Space-saving (requires installation of sensor unit only)

- Adjustment of optical axis not required

- Reflective transparent objects detectable

- Color differentiation possible

Applications

- Part presence

- Error proofing

- Fill measurement

- Product height

- Lid presence

Background suppression allows the sensor to ignore a very reflective background almost directly behind a dark, less reflective object. In many applications, it is the ideal diffuse sensing mode; however, background suppression sensors are more complex and, therefore, more expensive than other diffuse models. For example, a background suppression sensor can detect corrugated cardstock to be printed without detecting the machine panel below the cardstock.

Background suppression sensors use sophisticated electronics and optics to actively sense both the object and the background instead of attempting to ignore the background behind an object. The two signals are compared, and the output will change state upon active detection of the object or the background.

Still trying to decide what type of photoelectric sensor will work best for your application? Feel free to email our tech support or give us a call at (847) 658-8130 and we’d be happy to assist in finding the right sensor for you!